QC Solar: vertical integration strategic layout, the leader of photovoltaic junction box industry

With the increasing global demand for sustainable energy, the photovoltaic industry, as an important part of green energy, is ushering in unprecedented development opportunities. It is predicted that by 2025, the global photovoltaic new installed capacity is expected to reach 330GW. The surge in demand for photovoltaic installations has directly driven the demand for modules in the market, and each photovoltaic module needs to be equipped with a set of junction boxes to ensure its efficient and stable operation. It is expected that in 2025, the demand for photovoltaic junction boxes will reach 1.13 billion sets.

一、Deep cultivation of the photovoltaic component industry leader

Since its establishment in 2005, QC Solar, with its deep industry experience and professional knowledge, has been full of rich experience, through 18 brilliant years. In 2022, QC Solar, successfully listed in Shenzhen Stock Exchange GEM, stock code 301278. The company adheres to technological innovation and vertically integrated production management, and continues to expand its product line, covering photovoltaic connectors, photovoltaic junction boxes, smart junction boxes and energy storage connectors, etc., with excellent product quality and cost efficiency, it has always maintained its industry leading position.

二、Layout vertical integration: shaping core competitive advantages

The vertical integration model of QC Solar is not only limited to production integration, but deeply runs through every link from raw material procurement to after-sales service. In the photovoltaic industry, the quality of raw materials plays a crucial role in the performance and stability of products. Through vertical integration, QC Solar can accurately control the quality of raw materials to ensure excellent product quality and reliability. This vertically integrated model not only makes QC Solar stand out in the fierce market competition, but also ensures that QC Solar is always at the forefront of the industry to provide customers with more efficient, safer and more reliable photovoltaic products and services.

Professional and precise: Create efficient quality

From the development and manufacturing of photovoltaic molds to injection molding, metal stamping and cleaning, cable stranding and extrusion, vulcanization of silicone seals, and wafer sealing and finished product assembly of semiconductor bypass devices, we always adhere to high standards in every core link, and rely on deep professional knowledge and technical accumulation, independently complete each step of the process. We know that quality is the cornerstone of the enterprise, and professionalism and precision is the key to shaping excellent quality.

Technology driven innovation: leading the forefront of the industry

In the context of continuous leaps in technology, the photovoltaic industry is booming at an unprecedented rate. With strong research and development capabilities, QC Solar has always maintained cutting-edge technological innovation in the industry through independently developed advanced technologies and deep vertical integration management mode. At the same time to reduce costs, continuously improve product quality and process precision.

After more than 10 years of unremitting research and development and production practice, QC Solar has made major breakthroughs in the core technology of photovoltaic junction boxes and connectors, especially in the aspect of panel bypass protection, and has realized the leapfrog development from ordinary rectifier diodes and Schottky diodes to integrated module diodes and professional IC control circuit structures. Launched a series of competitive high-quality products. In addition, in the field of semiconductor bypass device wafer encapsulation, QC Solar also uses advanced packaging and testing technologies to ensure the efficient operation of wafer packaging and testing processes, which greatly improves the performance and stability of products.

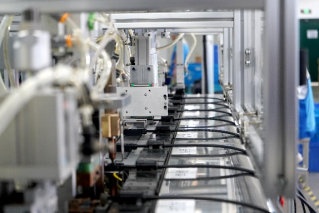

Strong production strength: to meet the diversified market demand

In order to meet the diversified needs of the market, we have set up manufacturing bases in Suzhou, Huai an, Nantong and Beijiang, Vietnam, and introduced advanced automatic production lines to ensure a stable supply of products. At the same time, in order to further improve production efficiency and optimize product quality, we have introduced international cutting-edge production equipment, integrated deep professional knowledge and technical accumulation, and successfully built a vertically integrated production management system. This system not only realizes the highly refined management of production costs and quality control, but also can quickly respond to the changing needs of the market, fully demonstrating the core competitiveness of vertical integration in the photovoltaic industry.

三、Looking Forward to the Future: Global Brand Layout Gradually Improving

In the global energy transition and green low-carbon trend, QC Solar with its keen market insight, continue to optimize the global brand layout, and actively explore new business areas. We not only promote our products and services to the world, but also set up manufacturing bases and sales networks in many countries and regions, in order to enhance brand influence and market share, and provide better photovoltaic connectivity solutions for global customers.

In the future, QC Solar will continue to deeply cultivate the photovoltaic industry, drive innovation with professional technology, constantly enhance technical strength, and enhance product competitiveness. At the same time, we actively explore business areas, keep up with the development trend of new energy, and strive to become the world's leading photovoltaic connection solution provider.