Revolutionary Innovation of QC Solar Photovoltaic Connectors: Crimping-free On-site Installation, Plug and Play

When constructing and installing new photovoltaic power stations in the wild, or renovating old power stations, or carrying out emergency repairs on faulty power stations in the wild, a large amount of on-site labor is usually required. Meanwhile, due to insufficient or no training, on-site construction workers may use incorrect crimping tools or incorrect crimping and fastening techniques when making electrical connections, resulting in unreliable actual crimping connections of photovoltaic connectors, high resistance, heat generation, loosening, lack of waterproofing and other issues. Eventually, it may lead to the overall shutdown of the photovoltaic power station and even fires caused by loose connections.

QC Solar (301278.sz) has newly launched a revolutionary innovative connector product: a photovoltaic connector that requires no on-site crimping and is plug-and-play. This connector can reduce on-site installation labor costs and time costs by 40%. It greatly improves the construction and maintenance speed of photovoltaic power stations. Meanwhile, the connection is more reliable, and there is no need for expensive and complicated crimping tools. It is fast and reliable.

01. Factory Installation Solution

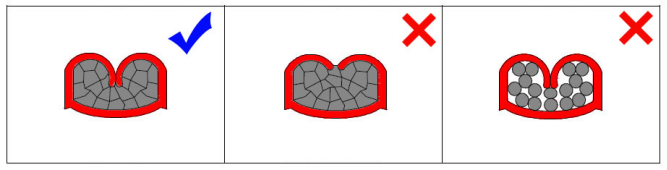

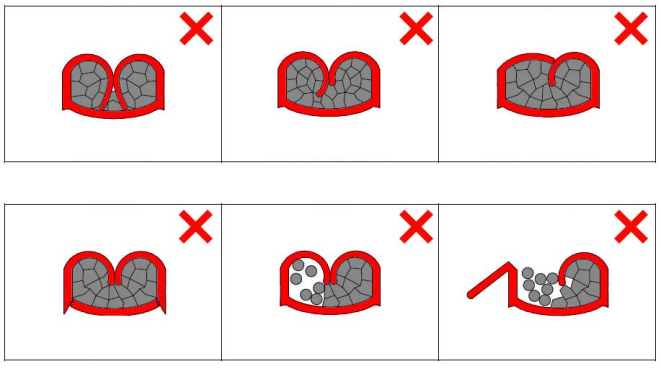

During the installation process of traditional connectors, the crimping technique is usually used to connect cables to conductive terminals. When assembling in the factory, through precise control of process parameters and analysis of terminal cross-section data, precise control of the crimping quality can be achieved, and the cable compression ratio can be controlled within 70% - 90%. However, in the on-site installation process, due to the lack of professional tools, the insufficiency of operators' skills, and the inconsistency in the quality of crimping pliers on the market, and even the use of non-professional tools such as vise for crimping, these factors may all bring serious potential safety hazards. There are even phenomena of using non-professional tools (such as vise) for crimping, which all pose potential safety risks.

02. On-site Installation Innovative Solution

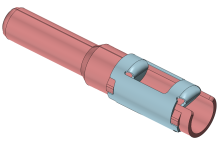

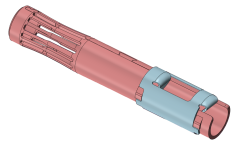

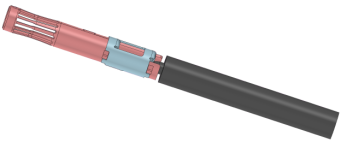

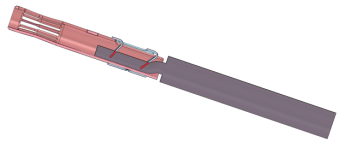

In response to the problem of non-standard operations when installing connectors on-site, QC Solar has launched an innovative Crimping-free Connector, which adopts the Push-in connection technology. By using pressure plates to apply pressure to the cables, it ensures that the cables are tightly combined with the conductive components, thus achieving a stable connection.

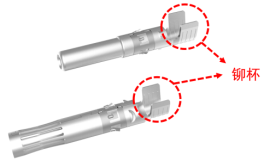

Unique Pressure Plate Design:

The stainless steel pressure plates are carefully designed with a unique bending angle, endowing them with a self-locking function.

Optimized Size and Structure

In addition, through fine adjustments to the size and structure, low insertion resistance and high pull-out force (meeting the IEC60352 Table1 standard) are achieved, ensuring a high contact force between the conductors and the conductive bodies. Considering that photovoltaic cables are usually composed of multiple strands of copper wires (meeting the IEC 60228 Class 5 standard), the pressure plates are designed in two places, effectively preventing the problem of the copper wires from warping after being inserted into the cables, and increasing the contact area between the cables and the conductive bodies of the connectors, making the connection tighter and further reducing the contact resistance.

This installation method not only significantly saves operation time but also ensures the reliability of the contact. Only one conductor needs to be prepared, inserted into the crimping point, and the nut tightened to complete a safe and reliable wiring process. The operation is simple and does not require any crimping tools.

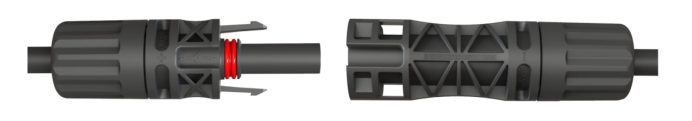

03. Application of the Crimping-free Connector

This Crimping-free Connector is a patented product, meeting the certification standards of IEC62852 and UL6703. It is applicable to cables with specifications of 4mm² and 6mm², has a rated voltage as high as 2000V, and can be plugged and mated with QC4.10 series connectors of QC Solar. Whether it is for installing small rooftop systems or large commercial solar power plants, it can provide fast and reliable solutions and greatly reduce installation time and labor costs.

Moreover, it is especially suitable for on-site renovation and maintenance work: for aging solar systems that need to replace connectors, the convenient installation of the Crimping-free Connector ensures that maintenance can be carried out quickly without the need for special tools.

Crimping-free Connector: The Innovative Choice for the Photovoltaic Industry

The Crimping-free Connector has brought an innovative solution to the photovoltaic industry. It not only simplifies the installation process and improves the reliability of connections but also effectively reduces the failure rate. Whether it is for installing new equipment, carrying out maintenance or expanding the system, it can ensure the efficiency and durability required for long-term success.